Selecting Butterfly Valves for Potable Water Systems: A Buyer’s Guide

Introduction: Why Valve Selection Matters for Potable Water

In potable water systems—including domestic water, drinking water, and municipal supply—the correct choice of valve is critical. The wrong selection can result in excessive metal leaching, bacterial growth, system downtime, and even legal risks.

Butterfly valves, with their compact structure, quick operation, low flow resistance, and cost efficiency, are widely used in water treatment, transmission, and distribution. However, not all butterfly valves are suitable for potable water applications.

Union Valve offers a complete range of butterfly valve solutions for industrial water, seawater treatment, HVAC systems, municipal water supply, and potable water applications.

For potable water, our butterfly valves are WRAS-certified, ACS-certified, and fully compliant with Australian WaterMark requirements, ensuring safe and compliant operation in the UK, France, Australia, and other regulated markets.

Key Requirements for Potable Water Butterfly Valves

1.Material Safety

Potable water butterfly valves must be manufactured from non-toxic, corrosion-resistant materials that comply with drinking water standards.

Body Materials

- 316/316L Stainless Steel – Excellent corrosion resistance (especially against chlorinated water), high mechanical strength, hygienic; preferred for premium potable water systems.

- Ductile Iron (lined with food-grade epoxy coating) – Economical and practical; must be non-toxic, fully compliant with potable water standards, and suitable for low-to-medium pressure systems.

Not permitted: Standard cast iron, leaded brass, or other materials that may leach harmful substances.

Disc Materials

Usually the same as the body (stainless steel) or stainless steel overmolded with food-grade rubber/PTFE.

Seat/Seal Materials

- EPDM – First choice for potable water; excellent aging, ozone, and chlorine resistance; non-toxic and odor-free.

- Food-grade Silicone Rubber – Good high/low-temperature resistance; slightly less wear-resistant than EPDM.

- PTFE – Exceptional chemical inertness; used for high-performance or special media applications. Any filler materials must also meet potable water standards.

Not permitted: NBR (Nitrile rubber) and other non-potable water grade elastomers.

Always request a supplier’s declaration of conformity and migration test reports to confirm no harmful substances will leach into the water.

2.Hygienic Design

- Zero Stagnation – Smooth internal surfaces without dead spots to prevent deposits and microbial growth.

- Easy Cleaning – For high-purity applications, use full-bore sanitary butterfly valves to facilitate CIP/SIP (Clean-in-Place/Sterilize-in-Place).

- Stem Sealing – Multi-seal arrangements to prevent external contamination.

3.Certifications & Standards

Potable water valves must meet relevant international certifications:

- NSF/ANSI 61 (USA) – Health effects standard for drinking water system components.

- NSF/ANSI 372 (USA) – Low-lead requirement (≤0.25%).

- WRAS (UK) – Approval for water fittings in the UK and many Commonwealth countries.

- ACS (France) – French sanitary approval for potable water contact materials.

- KTW/W270 (Germany) – German approval for rubber and plastic in drinking water contact.

- WaterMark (Australia) – Mandatory Australian certification ensuring compliance with building regulations and safety standards.

Union Valve’s potable water butterfly valves are WRAS- and ACS-certified and comply fully with Australian WaterMark requirements, guaranteeing market compliance and long-term reliable operation.

How to Select the Right Butterfly Valve for Potable Water

1.Size & Pressure Rating

- Nominal Diameter (DN) – Match to pipeline diameter and required flow rate.

- Pressure Rating (PN/Class) – Select higher than the system’s maximum operating pressure, accounting for water hammer; common ratings include PN10, PN16, and Class 150.

2. End Connections

- Wafer Type – Compact, economical; clamped between flanges.

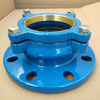

- Flanged Type – Robust and stable; ideal for large diameters or higher pressure.

- Lug Type – Threaded inserts for single-end disassembly; suitable for pipeline ends.

3. Operation Methods

- Lever – For small diameters; quick operation.

- Gear Operated – For medium/large sizes; reduced effort but slower.

- Electric Actuator – For automated control.

- Pneumatic Actuator – Fast response; requires clean, dry air.

4. Temperature Suitability

- EPDM: -20°C to +120°C (short-term up to +130°C)

- Silicone & PTFE: Wider temperature range; check compatibility with pressure and media.

Common Applications for Potable Water Butterfly Valves

- Municipal Water Plants – Clear water inlet/outlet control, pump isolation.

- Building Water Supply Systems – Zone control, pump inlet/outlet isolation.

- Water Treatment Plants – Filtration, disinfection, and softening processes.

- Drinking Water & Purified Water Systems – Full-bore sanitary butterfly valves recommended.

- Combined Firefighting & Domestic Water Systems – Must also meet potable water standards.

Procurement Checklist for Potable Water Butterfly Valves

- Define Application Requirements – Water quality (chlorinated/non-chlorinated), temperature, pressure, flow, and operation method.

- Verify Compliance – Obtain valid certification documents for the exact model and material combination.

- Select Materials & Seals – 316L stainless steel + potable water grade EPDM recommended.

- Choose End Connection & Structure – Based on installation space and maintenance needs.

- Evaluate Supplier Capability – Review quality control systems, test reports, and reference projects.

- Consider Maintenance – Ensure seals and actuators are easy to replace.

Purchasing butterfly valves for potable water systems is not only a technical selection, but also a guarantee of water quality and safety. Compliant materials, safe design and authoritative certification are essential.

Union Valve is committed to providing high quality butterfly valves for potable water projects around the world. Our products strictly comply with the requirements of potable water certification in many countries and regions, and our butterfly valves have been in stable operation in municipal water supply, building water supply and water purification projects in many countries.

By choosing Union Valve, you are choosing a long-term, stable and safe guarantee for your project. If you have any further questions, please contact us.